Design a Water Level Controller Using Pic16f877a Microcontroller

Contents

- 1 1. Power Supply Section

- 2 2.Water Level Sensing Section

- 3 3. Receiver Section

- 4 4. Controlling Section

- 4.1 Circuit Diagram

- 4.2 MikroC Code

- 5 Working

- 6 Download Here

Here is a simple, versatile project which indicates the level of water and automatically controls it by using PIC Microcontroller. The Water Level Sensing Section senses the level of water in the tank and sends it (wireless) to the Receiver Section. Receiver Section is connected to the Controlling Section, which process the received information and produces visual, sound indications and controls the operation of the motor whenever required. The project is divide into 4 sections.

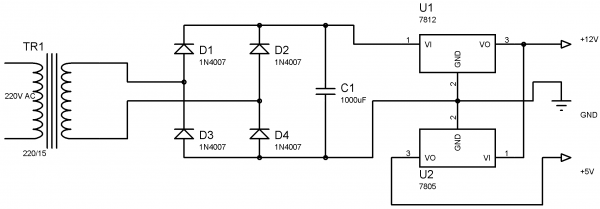

1. Power Supply Section

Power Supply section provides required supply for Receiver and Controlling modules. Receiver module requires +5V power supply. Controller module requires +5v and +12v supply. Circuit Diagram:

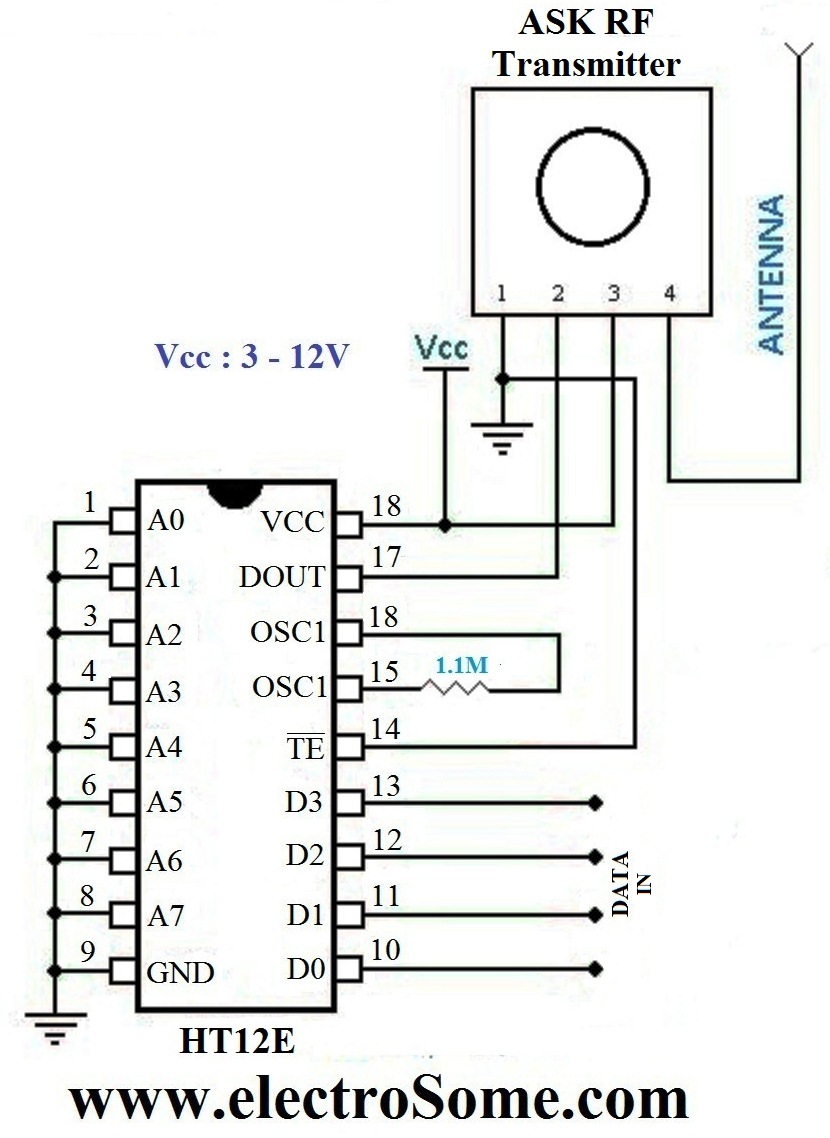

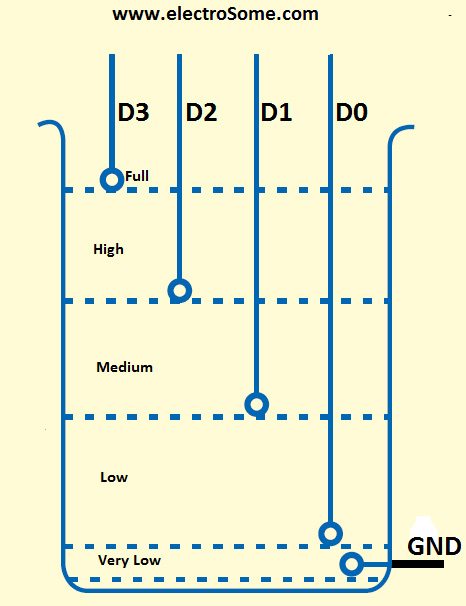

2.Water Level Sensing Section

Level Sensor module is made of with HT12E encoder and ASK (Amplitude Shift Keying) RF transmitter. This circuit can be drive using 9V battery. For more details about this transmitter, please read the article Wireless RF Transmitter and Receiver using ASK RF Module. This circuit is placed near the Water Tank and connected to the tank as show in the figure below.

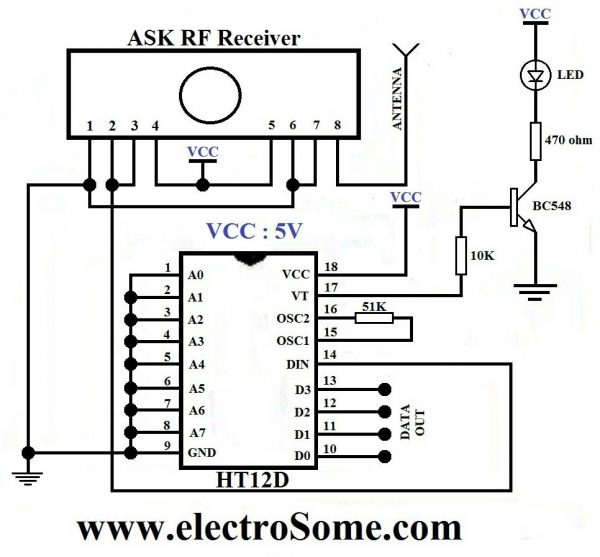

3. Receiver Section

Receiver Module is made of with HT12D decoder and ASK RF receiver. The data transmitted by the Sensor module is received by this module and is given to the Controlling Module. For more details about this receiver, please read the article Wireless RF Transmitter and Receiver using ASK RF Module.

4. Controlling Section

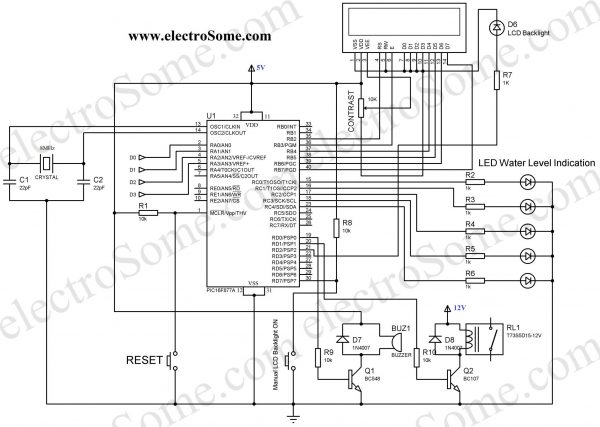

Circuit Diagram

The soul of the Controlling Section is PIC16F877A. It process the data given by the Receiver Section. LCD Display, LED Indications and Motor status are updated according to the data. You can download the hex file and mikroC Source Code at the bottom of this article.

MikroC Code

// LCD module connections sbit LCD_RS at RB2_bit; sbit LCD_EN at RB3_bit; sbit LCD_D4 at RB4_bit; sbit LCD_D5 at RB5_bit; sbit LCD_D6 at RB6_bit; sbit LCD_D7 at RB7_bit; sbit LCD_RS_Direction at TRISB2_bit; sbit LCD_EN_Direction at TRISB3_bit; sbit LCD_D4_Direction at TRISB4_bit; sbit LCD_D5_Direction at TRISB5_bit; sbit LCD_D6_Direction at TRISB6_bit; sbit LCD_D7_Direction at TRISB7_bit; // End LCD module connections char txt1[] = "Water"; char txt2[] = "Level"; char txt3[] = "Indicator"; char txt4[] = "And Controller"; char mtr1[] = "Motor "; char mtr2[] = "OFF"; char mtr3[] = "ON"; char wtr1[] = "Level: "; char wtr2[] = "Very Low"; char wtr3[] = "Low"; char wtr4[] = "Medium"; char wtr5[] = "High"; char wtr6[] = "Full"; void main() { int i = 0; int c = 16; int b = 0; CMCON = 0x07; ADCON1 = 0x06; TRISA = 0x0F; // set direction to be input PORTA = 0x00; PORTD = 0x00; PORTC = 0x00; TRISB = 0x00; // set direction to be output TRISC = 0x00; // set direction to be output TRISD = 0x80; // set direction to be output PORTD.F2 = 1; PORTD.F7 = 1; Lcd_Init(); // Initialize LCD Lcd_Cmd(_LCD_CLEAR); // Clear display Lcd_Cmd(_LCD_CURSOR_OFF); // Cursor off Lcd_Out(1,1,txt1); // Write text in first row Lcd_Out(2,1,txt2); // Write text in second row Delay_ms(500); Lcd_Cmd(_LCD_CLEAR); // Clear display Lcd_Out(1,1,txt3); // Write text in first row Lcd_Out(2,1,txt4); // Write text in second row Delay_ms(500); // Moving text for(i=0; i<15; i++) { Lcd_Cmd(_LCD_SHIFT_RIGHT); Delay_ms(125); } i=0; //Motor Status OFF do { Lcd_Cmd(_LCD_CLEAR); Lcd_Out(1,1,wtr1); Lcd_Out(2,1,mtr1); if(c>0) { PORTD.F2 = 1 //LCD Backlight ON c--; } else PORTD.F2 = 0; //LCD Backlight OFF if(b>0) { PORTD.F0 = 1; //Buzzer ON Delay_ms(125); PORTD.F0 = 0; //Buzzer OFF b--; } if(PORTD.F7 == 0) //Manual Backlight ON c = 16; if(PORTA == 0x0F) { PORTD.F1 = 1; Lcd_Out(1,8,wtr2); Lcd_Out(2,7,mtr3); PORTC = 1; if(i == 0) { c = 16; //Backlight b=3; //Buzzer } i=1; } else if(PORTA == 0x0E) { Lcd_Out(1,8,wtr3); if(i == 1) Lcd_Out(2,7,mtr3); else Lcd_Out(2,7,mtr2); PORTC = 3; //LED Bar } else if(PORTA == 0x0C) { Lcd_Out(1,8,wtr4); if(i == 1) Lcd_Out(2,7,mtr3); else Lcd_Out(2,7,mtr2); PORTC = 7; //LED Bar } else if(PORTA == 0x08) { Lcd_Out(1,8,wtr5); if(i == 1) Lcd_Out(2,7,mtr3); else Lcd_Out(2,7,mtr2); PORTC = 15; //LED Bar } else if(PORTA == 0x00) { Lcd_Out(1,8,wtr6); Lcd_Out(2,7,mtr2); PORTD.F1 = 0; // Motor OFF if(i == 1) { c = 16; //Backlight b = 3; //Buzzer } i=0; //Motor Status Updated PORTC = 31; //LED Bar } else PORTA = 0x0F; Delay_ms(125); }while(1); // Endless loop } Working

For the transmission and reception of data we have used Holtek encoder-decoder pair of HT12E and HT12D. Both of them are CMOS ICs working voltage ranges from 2.4 to 12v. The oscillator resistances are chosen according to the datasheet. When water level raises, the data pins of the encoder will be grounded corresponding to the level of water, which will be transmitted to the Receiver via ASK RF module. The received data is decoded by the decoder HT12D. LED on the receiver indicates that it is receiving data. Then the data is given to the PIC for processing.

| D0 | D1 | D2 | D3 | Status |

|---|---|---|---|---|

| 0 | 0 | 0 | 0 | All data pins are grounded, indicates tank is Full. |

| 0 | 0 | 0 | 1 | Water level is below D3 and above D2, indicates High level. |

| 0 | 0 | 1 | 1 | Water level is below D2 and above D1, indicates Medium level. |

| 0 | 1 | 1 | 1 | Water level is below D1 and above D0, indicates Low level. |

| 1 | 1 | 1 | 1 | Water level is below D0, indicates Very Low level. |

When the water level becomes Very Low, the motor will turned ON, buzzer sounds and the LCD backlight will automatically turned ON for 5 seconds. After this, when the water level reaches Full level, the motor will automatically turned OFF, buzzer sounds and the LCD backlight will automatically turned ON for 5 seconds. During normal operation you can manually turn on LCD backlight by pressing the Push button switch. The LCD indicates the Level of water ('Very Low', 'Low', 'Medium', 'High','Full') and the status of the motor ('ON' or 'OFF'). The LED bar will also indicate the level of water.

Download Here

You can download the hex file, mikroC source code, PCB Design, Layout, Proteus and Orcad files here.

- Water Level Indicator Controller using PIC

Design a Water Level Controller Using Pic16f877a Microcontroller

Source: https://electrosome.com/water-level-indicator-controller-pic/

0 Response to "Design a Water Level Controller Using Pic16f877a Microcontroller"

Postar um comentário